STATE OF MARYLAND

DHMH

DHMH

Maryland Department of Health and Mental Hygiene

6 St. Paul Street, Suite 1301 ! Baltimore, Maryland 21202

Martin O’Malley, Governor – Anthony G. Brown, Lt. Governor – John M. Colmers, Secretary

Office of Food Protection and Consumer Health Services

Alan Taylor, R.S., Director

Guidelines for Submitting a Hazard Analysis Critical Control Point (HACCP) Plan

Health-General Article, §21-321, Annotated Code of Maryland, and the Code of Maryland Regulations (COMAR) 10.15.03 Food Service Facilities require that plans and specifications be submitted to the Department when a person proposes to construct, remodel or alter a food establishment, or convert or remodel an existing building for use as a food establishment. Plans and specifications for the building and equipment, and information regarding the foods to be prepared, processed, or manufactured are required. This information will be used to classify the facility as high, moderate, or low priority. Definitions of priority assessment levels are found in COMAR 10.15.03.33C.

A HACCP plan is required for all high or moderate priority facilities. Facilities which serve only hand dipped ice cream or commercially packaged potentially hazardous foods do not require a HACCP plan. The following information is intended to assist you in providing the necessary information for both priority assessment and HACCP plan development.

Contents

A.Priority Assessment Information

B.General Food Handling Information and Procedures

C.HACCP Plan Required Contents

D.HACCP Plan Formatting Instructions

E.Obtaining Maryland Retail “Food Service Facility” Regulations

F.Model HACCP Formats and Sample Written Employee Training

November 2008

410-767-8400 ! Fax 410-333-8931

Toll Free 1-877-4MD-DHMH ! TYY for Disabled - Maryland Relay Service 1-800-735-2258

Web Site: www.dhmh.state.md.us

A.Priority Assessment Information

1.Menu or foods – Provide a copy of the menu or a written description of the foods to be prepared and served.

2.Food service system – Specify the food preparation and service systems you will use, i.e. cook-serve, cook-chill-reheat-hot hold-serve, cold hold-serve.

3.Population served – Specify whether you serve food in a health care facility, as defined in COMAR 10.15.03.02B(38).

B.General Food Handling Information and Procedures (only required for

facilities classified as “high” or “moderate”):

1.Describe how you will ensure that all foods are obtained from approved sources.

2.Specify how cross-contamination from raw to cooked or ready-to-eat foods will be prevented.

3.Indicate how frozen potentially hazardous food will be thawed.

4.Indicate how potentially hazardous food will be cooled, i.e. ice baths, shallow pans, rapid chill.

5.List the foods or categories of foods that will be prepared more than 12 hours in advance of service.

6.Specify whether any prepared foods are distributed off-premises.

7.Specify whether any refrigerated foods are received which require storage temperatures below 41°F.

8.Indicate whether reduced oxygen packaging of food, as defined in COMAR 10.15.03.02B(63), will be conducted onsite.

9.Include specific information for any processes or procedures which incorporate:

!“Time-only” control (see COMAR 10.15.03.08),

!“Pooling” of eggs (see COMAR 10.15.03.09D), and/or

!Serving raw or undercooked animal foods (see COMAR 10.15.03.10 C, D & F).

410-767-8400 ! Fax 410-333-8931

Toll Free 1-877-4MD-DHMH ! TYY for Disabled - Maryland Relay Service 1-800-735-2258

Web Site: www.dhmh.state.md.us

C.HACCP Plan Required Contents

The plan must include:

1.Identification of Critical Control Points (CCP). CCPs generally include cooking, cooling, reheating, cold holding, and hot-holding, but other steps may be included if needed for a specific food. Note that cold food preparation, like chopping, mixing and slicing, is not a CCP step. Hazards are controlled during those processes by following Good Retail Practices (GRPs), sometimes referred to as Standard Operating Practices (SOPs).

2.Critical limits for each CCP.

3.Monitoring procedures for each CCP.

4.The corrective action that will be taken if there is a loss of control at a CCP due to such factors as employee error, equipment malfunction, or power failure

5.Verification procedures that will ensure proper monitoring of each CCP such as calibration of cooking and holding equipment and thermometers, and maintenance and review of records such as temperature logs. Using logs for record keeping is strongly encouraged, but not required, as long as the facility can demonstrate that temperatures are routinely monitored, as described in the HACCP plan, and that specified corrective actions are taken when critical limits are not met.

6.A list of equipment used to support the proposed food service systems and maintain control at each CCP.

7.Written procedures for employee training on HACCP procedures (see attached example in section “F”).

410-767-8400 ! Fax 410-333-8931

Toll Free 1-877-4MD-DHMH ! TYY for Disabled - Maryland Relay Service 1-800-735-2258

Web Site: www.dhmh.state.md.us

D.HACCP Plan Formatting Instructions

The HACCP plan for your facility should be developed in a format which is easy for your employees to use. Once approved, this document must be readily available in the food preparation area of each facility. Examples of acceptable methods include:

1.Listing each CCP separately, with the menu items that utilize the CCP, the critical limits, monitoring procedures, corrective action, verification methods for that CCP, and the equipment used to control the CCP (see attached example #1),

2.Using a HACCP flow diagram and chart for selected menu items or groups of menu items (see attached example #2),

3.Incorporating each CCP and the monitoring, corrective actions, and equipment used, directly into the recipe or preparation instructions (see attached example #3), or

4.Using the “Process Approach” as advocated by the US Food and Drug Administration. (see attached example #4).

E.Obtaining Maryland Retail “Food Service Facility” Regulations (COMAR 10.15.03, effective 12/17/07):

!Via online access- go to this link and follow the directions below: http://www.dsd.state.md.us/comar/comar.htm

1.Click on the 3rd or bottom red circle on the main search page of the COMAR website (see link above) and search by "Access through table of contents structure",

2.From the drop down list, select: Title 10 "Department of Health and Mental Hygiene",

3.Click on: Subtitle 15, "Food",

4.Click on: 10.15.03 "Food Service Facilities". From this page, you must click on each of the 39 individual regulations separately to view the entire text.

!For a paper copy- contact the local health department in your area.

F.Model HACCP Plan Formats (Examples #1-4) and Sample Written

Employee Training Procedure (see following pages):

410-767-8400 ! Fax 410-333-8931

Toll Free 1-877-4MD-DHMH ! TYY for Disabled - Maryland Relay Service 1-800-735-2258

Web Site: www.dhmh.state.md.us

Model HACCP Plan - Example #1 (Listing CCPs Separately)

(shown for “Cooling” step)

CCP: ___COOLING________________

CCP and Critical Limits:

Foods are cooled from 135" F to 70" F within 2 hours, and from 70" to 41" F within an additional 4 hours.

Monitoring:

Internal product temperature of food is taken at 1.5 and 6 hours with a metal stem thermometer.

Corrective Actions:

If food is not ! 70" F at 1.5 hours, food will be iced, stirred, or broken into smaller containers. Food that has not reached 41" F within 6 hours will be discarded.

Verification:

Review cooling logs. (Note: An alternate method would be for the supervisor to visually observe that temperatures are taken at the proper times and, if not taken or not satisfactory, that corrective actions listed above are taken.)

Equipment:

Blast chiller, Walk-in cooler

Menu items using this CCP:

Fried chicken (cook, hot hold, cool, prepare for salad, cold hold, serve)

Macaroni and Cheese (cook, hot hold, cool, reheat, hot hold, serve or discard)

Mashed Potatoes (cook, hot hold, cool, reheat, hot hold, serve or discard)

Rice (cook, hot hold, cool, reheat, hot hold, serve or discard)

410-767-8400 ! Fax 410-333-8931

Toll Free 1-877-4MD-DHMH ! TYY for Disabled - Maryland Relay Service 1-800-735-2258

Web Site: www.dhmh.state.md.us

Model HACCP Plan - Example #1 (continue, shown for “Cooking” step)

CCP: ___COOKING________________

CCP and Critical Limits: Foods are cooked to temperature below for specified time:

Shell eggs cooked for immediate service, fish, meat, and all other potentially hazardous food not specified below cooked to 145°F for 15 seconds.

Shell eggs cooked other than for immediate service, ground fish and meats, commercially raised game animals, and injected meats cooked to 155°F for 15 seconds.

Whole roasts (for rare roast beef) cooked to 130°F and held for at least 112 minutes.

Poultry; stuffed meat, stuffed pasta or poultry; or stuffing containing fish meat, or poultry cooked to 165°F for 15 seconds.

Raw animal foods cooked to 165°F and held for 2 minutes, when using microwave oven for cooking.

Fruits, vegetables, and commercially processed food for hot holding cooked to at least 135°F.

Undercooked seared beefsteak cooked to 145° F for 15 seconds, must have a “cooked” color change on surface, and regulatory approval of process used.

Monitoring:

Internal product temperature of food is taken at completion of cooking time using a thermocouple with a metal probe.

Corrective Actions:

If food has not reached required temperature for the specified time, continue cooking. Recheck temperature after additional cooking to make sure standard is reached.

Verification:

Review cooking temperature logs. (Note: An alternate method would be for the supervisor to visually observe that temperatures are taken at the proper times and, not satisfactory, food is returned to the cooking equipment until the required time and temperature standards are met.)

Equipment: Oven, Range

Menu items using this CCP:

Fried chicken (cook, hot hold, cool, prepare for salad, cold hold, serve)

Macaroni and Cheese (cook, hot hold, cool, reheat, hot hold, serve or discard)

Mashed Potatoes (cook, hot hold, cool, reheat, hot hold, serve or discard)

Rice (cook, hot hold, cool, reheat, hot hold, serve or discard)

410-767-8400 ! Fax 410-333-8931

Toll Free 1-877-4MD-DHMH ! TYY for Disabled - Maryland Relay Service 1-800-735-2258

Web Site: www.dhmh.state.md.us

HACCP Plan (Example #1 Form)

CCP: ___ ________________

CCP and Critical Limits:

Monitoring:

Corrective Actions:

Verification:

Equipment:

Menu items using this CCP:

410-767-8400 ! Fax 410-333-8931

Toll Free 1-877-4MD-DHMH ! TYY for Disabled - Maryland Relay Service 1-800-735-2258

Web Site: www.dhmh.state.md.us

Model HACCP Plan - Example #2 (Chart Method)

Facility: ABC Restaurant Preparer: Don Smith Date: 00/00/00

Food Item: Chicken Noodle Soup

Flow diagram or descriptive narrative of the food preparation steps:

Cook chicken (CCP 1)_> Prepare soup > Cook (CCP 1) > Hot Hold (CCP 2) > Cool (CCP 3) > Reheat (CCP 4) > Hot Hold (CCP 2) > Discard

HACCP Chart

Critical Control Points (CCP)

CCP 1

Cook chicken to a minimum of 165" F.

Heat soup to a minimum of 165" F.

Check internal temperature.

Continue to cook until food reaches 165" F.

CCP 2 |

|

|

Hot Hold soup at a minimum of 135" |

Check internal temperature of the |

Rapidly reheat soup to 165" F if found |

F. |

soup every 2 hours. |

out of temperature for less than 2 |

|

|

hours. Discard if greater than 2 hours. |

CCP 3 |

|

|

Cool soup from 135" F to 70" F within |

Check internal temperature of soup |

If soup has not reached 70" F in the |

2 hours, and from 70" F to 41" F within |

at 1.5 and six hours. |

first 1.5 hours, separate into smaller |

an additional 4 hours. |

|

containers and place in freezer. |

|

|

If soup has not cooled to 41" F within |

|

|

6 hours, discard. |

CCP 4 |

|

|

Reheat cooled soup as needed to |

Check internal temperature. |

Continue to reheat until food reaches |

165" F. |

|

165" F. |

(Hot hold for service using CCP 2 |

|

|

above. Any soup remaining on steam |

|

|

table at end of day will be discarded.) |

|

|

Verification: Monitor temperature logs, and/or observe temperature monitoring and calibration practices.

Equipment utilized at each Critical Control Point listed in above chart:

CCP 1: Oven, Range

CCP 2: Soup wells on steam table

CCP 3: Walk-in refrigerator, freezer

CCP 4: Oven, Range

410-767-8400 ! Fax 410-333-8931

Toll Free 1-877-4MD-DHMH ! TYY for Disabled - Maryland Relay Service 1-800-735-2258

Web Site: www.dhmh.state.md.us

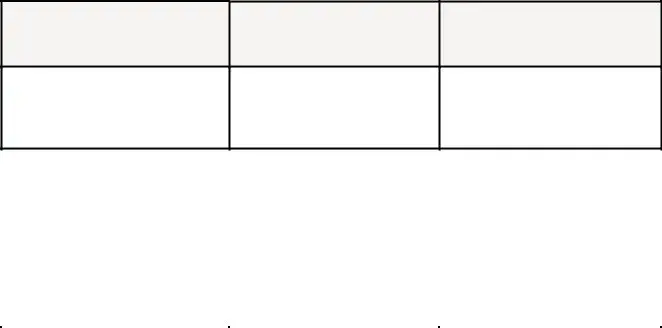

HACCP Plan (Example #2 Form)

Facility:Preparer:Date:

Food Item:

Flow diagram or descriptive narrative of the food preparation steps:

HACCP Chart

Critical Control Points (CCP)

Verification:

Equipment utilized at each Critical Control Point listed in above chart:

CCP 1:

CCP 2:

CCP 3:

410-767-8400 ! Fax 410-333-8931

Toll Free 1-877-4MD-DHMH ! TYY for Disabled - Maryland Relay Service 1-800-735-2258

Web Site: www.dhmh.state.md.us

Model HACCP Plan - Example #3 (Recipe Method)

Menu Item: Hamburger Pie

Ingredients |

Procedures |

CCP? |

Monitoring |

Corrective |

Verification |

|

|

|

Procedure |

Action |

Procedures |

10 lbs ground |

Thaw meat in walk-in |

No |

|

|

|

beef |

cooler |

|

|

|

|

1 lb each |

Wash and dice. Use |

No |

|

|

|

onions, celery, |

immediately or store in |

|

|

|

|

green pepper. |

cooler. |

|

|

|

|

2 pounds |

Shred cheese and store in |

|

|

|

|

American |

cooler until needed. |

|

|

|

|

cheese |

|

|

|

|

|

¾ gallon |

Braise beef, onions and |

Yes |

Monitor internal |

Continue cooking. |

Manager checks |

tomato soup, |

peppers on stove until the |

|

temperature with |

|

thermometer |

2 tsp. |

mixture reaches 155" F. |

|

stem |

|

calibration log and |

Worcestershire |

Add remaining ingredients |

|

thermometer |

|

observes |

sauce, 2 T salt, |

and return pot to 155" F. |

|

periodically |

|

temperature |

1 T pepper |

|

|

during cooking |

|

monitoring by |

|

|

|

process. |

|

employees. |

1 bag Mashed |

Prepare potatoes according |

No |

|

|

|

Potato Flakes |

to directions on bag. |

|

|

|

|

|

Spread into pans. Top with |

|

|

|

|

|

beef mixture and cheese. |

|

|

|

|

|

Bake pie in convection |

Yes |

Monitor internal |

Continue cooking. |

Manager checks |

|

oven at 325" F for |

|

temperature with |

|

thermometer |

|

approximately 1 hour, until |

|

stem |

|

calibration log and |

|

internal temperature |

|

thermometer |

|

observes |

|

reaches 155" F. |

|

periodically |

|

temperature |

|

|

|

during cooking |

|

monitoring by |

|

|

|

process. |

|

employees. |

|

Place on steam table for |

Yes |

Check product |

Discard if product |

Manager checks |

|

hot holding at 135" F. |

|

internal |

found below 135" |

thermometer |

|

|

|

temperature |

F for more than 2 |

calibration log and |

|

|

|

hourly. |

hours. If below |

observes |

|

|

|

|

135" F for less |

temperature |

|

|

|

|

than 2 hours, |

monitoring by |

|

|

|

|

rapidly reheat |

employees. |

|

|

|

|

using procedure |

|

|

|

|

|

below. |

|

|

Cool by placing un-served |

Yes |

Check product |

Use ice bath if |

Manager observes |

|

product in shallow pans |

|

internal |

food has not |

procedure and |

|

with product thickness of |

|

temperature |

cooled to 70" F |

reviews |

|

no more than 2”. Cool in |

|

every 2 hours. |

within 2 hours. |

temperature logs. |

|

blast chiller from 135" F to |

|

|

Discard product |

|

|

70" F within 2 hours, and |

|

|

that does not reach |

|

|

from 70" F to 41" F within |

|

|

41" F within 6 |

|

|

an additional 4 hrs. |

|

|

hours. |

|

|

Reheat product in |

Yes |

Check product |

Continue cooking. |

Manager checks |

|

convection oven to 165" F |

|

internal |

|

thermometer |

|

within 2 hours. |

|

temperature |

|

calibration log and |

|

|

|

|

|

observes |

|

|

|

|

|

temperature |

|

|

|

|

|

monitoring by |

|

|

|

|

|

employees. |

410-767-8400 ! Fax 410-333-8931

Toll Free 1-877-4MD-DHMH ! TYY for Disabled - Maryland Relay Service 1-800-735-2258

Web Site: www.dhmh.state.md.us

DHMH

DHMH